letlapa la phetoho

Pmolemo oa roduct:

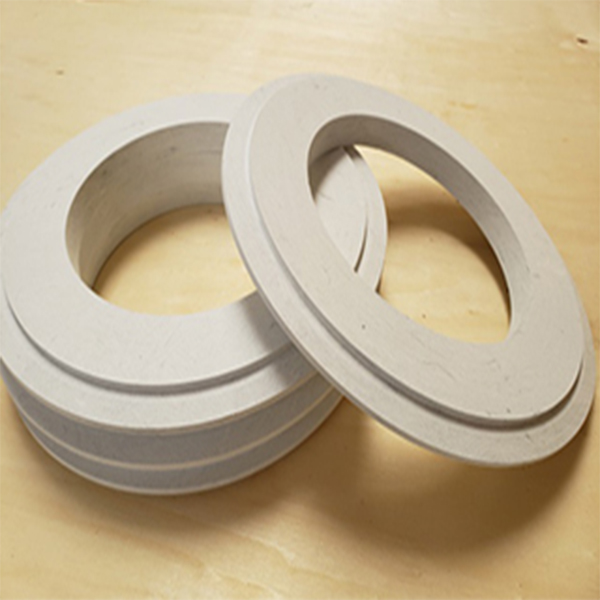

1. Thepa e ntle e sa kolobiseng, bokaholimo bo boreleli, ho nepahala ha ts'ebetso ea geometri le litšenyehelo tse tlase tsa tlhokomelo.

2. Ha ho na delamination le peeling phenomenon, e ka fokotsang tšilafalo ea aluminiamo e qhibilihisitsoeng le ho etsa hore aluminium e hloekisitsoeng e se na tšilafalo..

3. Ho hanyetsa khoholeho, ho hanyetsa mocheso o motle oa mocheso, ho ntlafatsa ho hanyetsa ha kutu ho tšepe e qhibilihisitsoeng.

4. Ho molemo ho sebelisa pente ea boron nitride (BN), 'me bophelo bo tloaelehile ka makhetlo a 450-800, e le ho boloka matla le ho fokotsa tšebeliso..

Litaelo tsa tšebeliso ea lisebelisoa tsa ho lahla:

1. Khetha lisebelisoa tse chesang tse ka holimo tsa ho lahlela lisebelisoa tsa sethaleng tsa litlhaloso tse lumellanang.

2. Kenya shuntpoleiti, letsoho, adaptarapoleiti, shunt tank, le lesale la graphite lehlakoreng le ka holimo la sethala, 'me u kenye letsoho, adapter plate, le reng ea graphite lehlakoreng le ka hare la kristallise ho netefatsa bohloeki, ha ho na tšenyo, le likheo.Ho molemo ho sebelisa pampiri ea fiber ea ceramic kapa kobo ea fiber ea ceramic ho tiisa tlase le tlase, e leng thuso bakeng sa ho boloka mocheso.

3. Ka mor'a hore ho kenngoe sethala sa ho lahla se chesang se chesang, ka mokhoa o ts'oanang futhumatsa sethala sa lisebelisoa tse kentsoeng le tse tloaelehileng ho 260-350 ° C.Ho ka sebelisoa ho baka motlakase kapa khase.Ha ho malakabe a bulehileng a lokelang ho ikopanya le lesela la ka hare la sehlahisoa, ho seng joalo mapetsong a tla hlahale tTšenyo ea hae e tla jaroa ke mosebelisi, e le hore e ka tlosa metsi a kristale a adsorbed mme a e sebelise ka mokhoa o sireletsehileng le ka katleho.