filthara lebokose le nang le boto ea filthara ea ceramic e sefang aluminium e qhibilihisitsoeng

Letlapa la graphite ha le tsoa mochining oa aluminium extrusion le phetha karolo ea ho tlotsa.Ka kakaretso, ho sebelisoa graphite e nang le majoe a mangata.Graphite e hloekileng haholo e ntle ebile e boreleli, 'me monyetla oa ho senya thepa ea aluminium o monyenyane haholo.Ho sebelisa thepa ena ea bohloeki bo phahameng ho tla eketsa haholo bophelo ba tšebeletso le ho boloka litšenyehelo ka mokhoa o batlang o lekana.

Lebitso la sehlahisoa: Aluminium profile graphite sheet

Litšobotsi tsa Sehlahisoa: Ts'ebetso e hlophisitsoeng E ikhethang ka tlhahiso ea lihlahisoa tse fapaneng tsa graphite, tse ka hlophisoang ho latela litlhoko tsa bareki!

1.Haeba u na le litšoantšo, ka kopo romela litšoantšo (CAD, PDF, litšoantšo tse entsoeng ka letsoho).

2.Hlalosa boholo, bongata, botenya, joalo-joalo.

3.Khetholla theknoloji ea ho sebetsa (ho itšeha ka mokhoa o bonolo, ho phunya, ho etsa likarolo tsa batho ba bong bo fapaneng, ho sila, ho sila le ho khaola, joalo-joalo).

4.Payment e ka etsoa ka mor'a quotation.

Hlokomela:Haeba boholo bo hlokeha hore bo nepahale ka ho khetheha, ka kopo hlalosa, hobane ho tla ba le mamello e itseng bakeng sa mekhoa e tloaelehileng e kang ho itšeha, ho sila le ho phunya.Haeba ho na le litlhoko tse nepahetseng bakeng sa likarolo tse nang le sebōpeho se khethehileng, le tsona li lokela ho hlalosoa esale pele.Ho thunya kelello ka hloko Likarolo: 1 Ho hanyetsa mocheso o motle 2 Ho tlotsa le ho hanyetsa ho roala 3 Ts'ebetso e ntle ea mocheso 4 Machining a profeshenale a nepahetseng

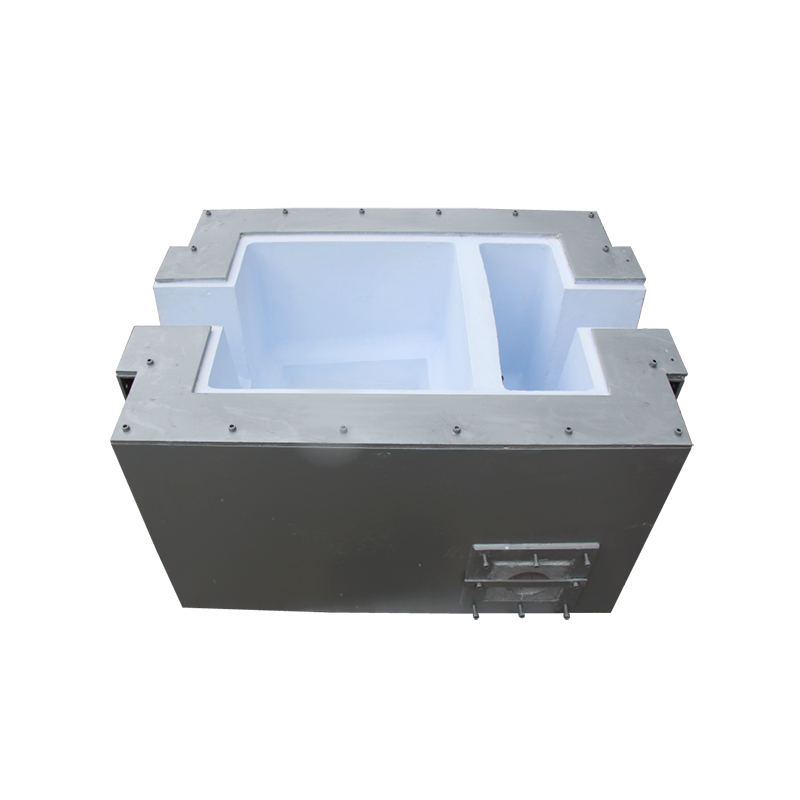

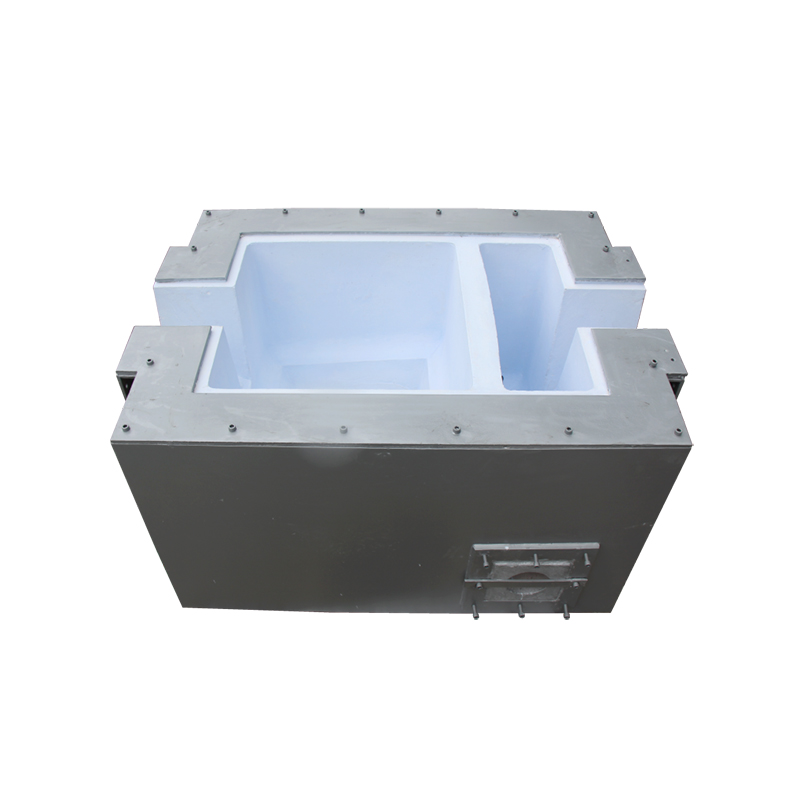

E loketse bakeng sa ho lahlela lits'ebetso tse nang le filtration ea foam e entsoeng ka reticulated.

1. E ka sebelisoa ka ho toba mocheso oa kamore ntle le ho tšoenyeha ka mocheso oa mocheso.

2. Ha ho na katoloso ea mocheso le conductivity e tlaase ea mocheso.

3. E ka phaphamala ka aluminium, e fokotsa monyetla oa ho kenyelletsa li-refractory.

1. Hloekisa lebokose la sefe.

2. Ka bonolo kenya poleiti ea sefe ka har'a lebokose la sefe, 'me u hatelle gasket e koalang ho pota-pota poleiti ea filthara ka letsoho ho thibela ho phalla ha aluminium e qhibilihisitsoeng.

3. Preheat lebokose la sefe le poleiti ea filthara ka ho lekana ho etsa hore li be haufi le mocheso oa aluminium e qhibilihisitsoeng.Preheat ho tlosa mongobo le ho thusa ho sefa hang hang.Ho futhumatsa ho ka etsoa ka ho futhumatsa motlakase kapa khase.Tlas'a maemo a tloaelehileng, ho nka metsotso e ka bang 15-30.

4. Ela hloko phetoho ea hlooho ea aluminium hydraulic ha u lahla.Hlooho e tloaelehileng ea khatello ea pele ke 100-150mm.Ha aluminium e qhibilihisitsoeng e qala ho feta, hlooho ea khatello e tla theoha ka tlase ho 75--100mm, ebe hlooho ea khatello e tla eketseha butle-butle.

5. Nakong ea mokhoa o tloaelehileng oa ho hloekisa, qoba ho kokota le ho thothomela poleiti ea filthara.Ka nako e ts'oanang, sehlatsoa se lokela ho tlatsoa ka metsi a aluminium ho qoba tšitiso e ngata haholo ea metsi a aluminium.

6. Ka mor'a ho hloekisa, tlosa poleiti ea filthara ka nako 'me u hloekise lebokose la filthara.

Ho theha maemo a boholo, ho fana ka ts'ehetso e ts'epahalang bakeng sa ho lemoha ka nepo ts'ebetso ea ho sefa ea poleiti ea filthara ea foam ceramic.Ntle le litlhaloso tse akaretsang, e ka etsoa le ho etsoa ho latela litlhoko tsa bareki.