lehare la saw mochining oa ho hula ho bona profil ea aluminium

Li-blades tsa Carbide li kenyelletsa likarolo tse ngata tse kang mofuta oa hlooho ea alloy cutter, thepa ea 'mele oa motheo, bophara, palo ea meno, botenya, sebōpeho sa leino, angle, aperture, joalo-joalo. lehare la saw.Ha u khetha lehare la sakha, ho hlokahala hore ho khethoe mofuta oa thepa ea ho sakha, botenya, lebelo la ho sakha, moo u eang teng, lebelo la ho fepa le bophara ba tsela ea ho sakha.

1. Carbide High-speed sawtooth shock resistance E tiisitsoe

Carbide e na le letoto la thepa e ntle haholo joalo ka boima bo phahameng, ho hanyetsa ho roala ho phahameng, ho tiea hantle, ho hanyetsa mocheso le ho hanyetsa kutu.

2. Sekhahla se phahameng sa ho itšeha, ho hata leino le bataletseng Ho khaola li-profile tse fapaneng tsa aluminium

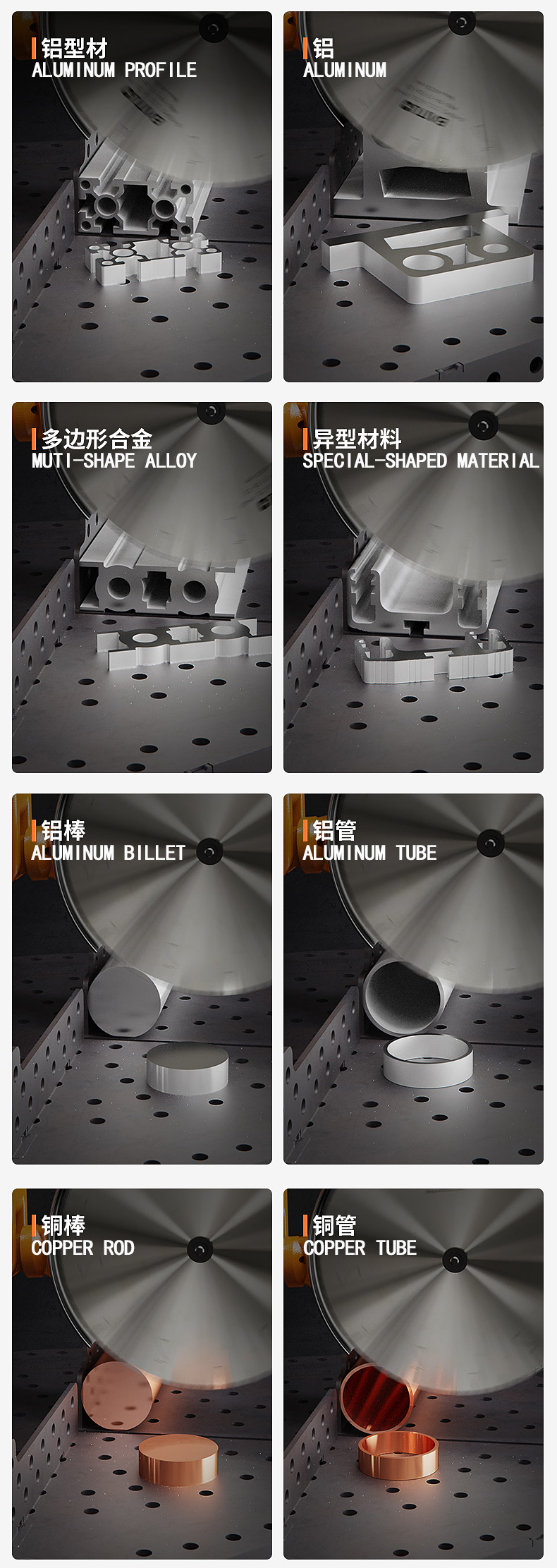

Lehare la sakha le meno a bataletseng li entsoe ka mahlale ho netefatsa ho nchocho ha lehare la sakha, le loketseng bakeng sa ho seha le ho seha lintlha tse fapaneng tsa aluminium, lipoleiti tsa aluminium le lithupa tsa aluminium.

3. Sebaka se sehiloeng se boreleli ebile ha se na burrs Ho itšeha ho sireletsehileng ntle le ho phatloha

E entsoe ka poleiti ea tšepe ea 75CR1, khanyetso e matla ea ho kobeha le lehare le bohale Seha lihlahisoa tse felileng ntle le li-burrs.

4. Moralo oa ho pholisa lesoba la moferefere Moralo o khutsitseng oa terata

poleiti ea aluminium e kenngoa ka polima e senyang le ho fokotsa matla, lerata le tlaase le lerōle le fokolang le fanang ka sebaka sa ho sebetsa se setle le se sireletsehileng.

5. Ho hanyetsa ka matla ho matla a ka ntle le khatello ea mocheso Ho itšeha ho sireletsehileng ntle le ho phatloha

E entsoe ka poleiti ea tšepe ea 75CR1, khanyetso e matla ea ho kobeha, lehare le bohale, ha ho burr sehlahisoa se felileng.

6. Ka potlako ho itšeha ka katleho, ho ka khaola mefuta eohle ea lihlahisoa tsa aluminium

Meno a ka ho le letšehali le a ka ho le letona a lehare la sakha a entsoe ka saense ho etsa bonnete ba hore lehare la sakha le bohale, le loketseng ho seha le ho seha lisebelisoa tse fapaneng tsa lehong le bonolo le le thata.

7. Balebeli ba melomo ea boemo ba lifofane ba fokotsa ho roala lisakha

Lehare le leng le le leng la sakha le na le sekoaelo se sireletsang, se ke keng sa rusa nako e telele, se sireletsa lehare la sakha ho tsoa ho oxidation, 'me se hanela tšusumetso le oxidation.