Mochini o Tsoelang Pele oa ho Lahlela oa Top Top Billet Bakeng sa Aluminium Foundry

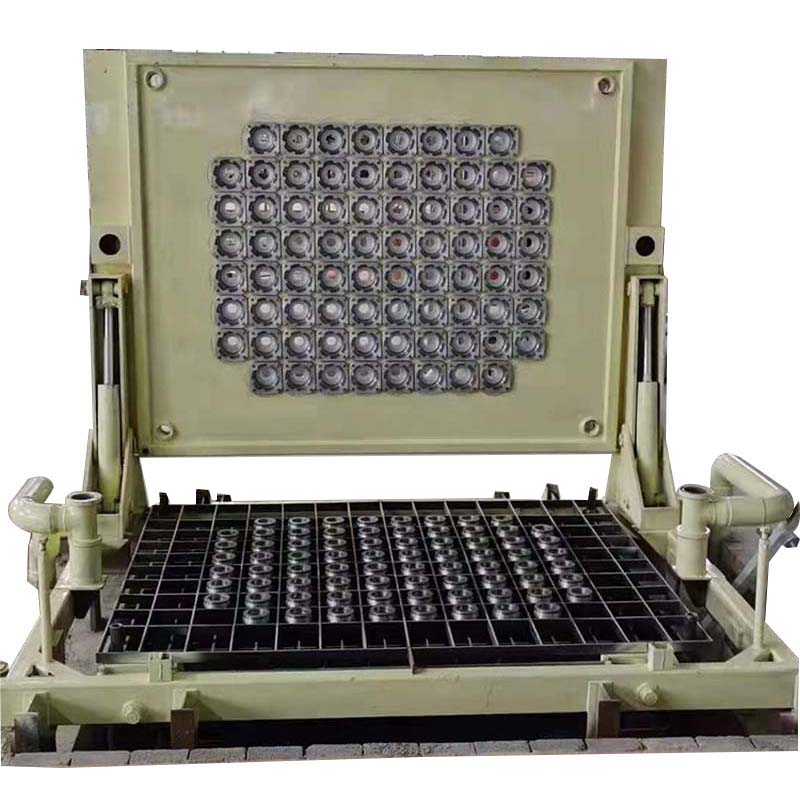

E na le mochini o hulang, thapo ea hydraulic, rack ea seliba, lifti, thapo ea tšepe, sistimi ea roller e tataisang.

Puller e entsoe ka enjene, mochini o fokotsang lisebelisoa tse kholo, thapo ea tšepe, rack jj.

Tafole ea Hydrauclic e entsoe ka pakete ea matla a hydraulic, tanka, tafole e phetholang, phala le li-valve joalo-joalo.

Tafole ea Hydraulic e kentsoe ntle le rack, hlobo e kaholimo e kentsoe holim'a tafole ea hydraulic, hlobo e tlase e kentsoe sethala sa lifti, nakong ea ho lahla, lifti e tla hula moeli o tlase, ebe o ea moeling oa bophahamo ho qeta ho ts'oara ka thapo ea tšepe.

Sebaka sa Tšimoloho:Guangdong, China

Boemo:E Ncha, E Ncha

Mofuta oa Mochini:mochini o lahlang, mochini oa ho lahla

Tlhahlobo ea video e hlahang:Fanetsoe

Tlaleho ea Teko ea Mechini:Fanetsoe

Mofuta oa Mmaraka:Sehlahisoa se Secha sa 2020

Warranty ea likarolo tsa mantlha:1 Selemo

Core Components:Gearbox, Motor, Gear, Pump

Palo ea li-volts:380V, 50HZ

Tiisetso:1 Selemo

Lintlha tsa bohlokoa tsa ho rekisa:Ho bonolo ho Sebetsa

Sebaka sa Showroom:Ha ho letho

Liindasteri tse sebetsang:Setsi sa Tlhahiso

Boima ba 'mele (KG):5000

Bolelele ba Billet:6 limithara

Billet bophara:70-406 limilimithara

bophara ba billet:3-16 inch

mokhoa oa ho lahla:ho lahla hot top top, air slipper casting, oil slipper casting

Kopo:Indasteri ea Foundry

Tšebeliso:Round Bar

Mofuta:Mochini o Tletseng o Tsoelang Pele oa Casiting

Theknoloji:Phetoho ea Mold e Ikemetseng

Mochini oa ho lahla o amohela sistimi ea ho lahla (boemo bo haufi-ufi-hot-top), liphofu tse maemong a nepahetseng ka dummy bar ka bo eona, 'me ha e na pampiri ea silicic acid.

1. Lebelo la ho lahla ke 0-250 mm/min (Ho laola lebelo le se nang mohato).Ho na le sistimi e fapaneng ea anti-speed e nang le matla a ho hula a 5-kw.

2. Ka mor'a ho qeta ho lahla, tafole ea ho lahla e ka phunyeletsa ho 89 ° C holim'a poleiti ka mokhoa o tsitsitseng oa tsamaiso ea hydraulic transmission. Automatic Billet Casting Machine.

3. Casting machine adots casting gystem (level dlose-packed hot. top), targetis Im right postlon with dumy bar automatball and i free from icic acid paper.

4. Lebelo la casing s 0-250 mm/min (Ho laola lebelo le sa hataneng}. Ho na le sistimi e fapaneng ea lebelo le matla la 5-kw racton.

5. Ka mor'a complrton ea caˢing, tafole ea ho lahlela e ka theolela ho 89*C n poleiti ka sistimi e tsitsitseng ea hydroulice tra nmisson.

| Modted Nio. | Bllet Size Da.bolelele ba x (mm) | Bllet qty (li-pcs) | Matla (liw) | Boima ba 'mele ka nako (k) | Tting Angle(") | She Lx W (mm) |

| ALM-ZB3.5" | 90*6000 | 54 | B | 5562 | 0-89 | 1900* 1900 |

| ALMZB5" | 0127*5000 | 32 | B | 5859 | 0-89 | 1800* 1800 |

| AM-Z86" | 01 52*6000 | 20 |

| 5876 | 0-89 | 1600*1600 |

| AM-287" | 178*6000 | 16 |

| 6446 | 0-89 | 1600* 1600 |

| M-288 | 9203*6000 | 12 | B | 6288 | 0-89 | 1600* 1600 |

| ALM-209" | 9230*6000 | 8 | B | 5382 | 0-89 | 1600* 1600 |

| A M-2B3.5" | 090*6000 | 100 | 11 | 10300 | 0-89 | 2400* 2400 |

| AUM-2B5" | *127*6000 | 60 | 11 | 10987 | 0-89 | 2300*2300 |

| ALMZB5.5" | 0140*6000 | 42 | 11 | 10468 | 0-89 | 2000*2000 |

| ALM-ZB6" | 152*6000 | 36 | 11 | 10577 | 0-9 | 2000*2000 |

| AM-2B7* | 178*6000 | 26 | 11 | 10476 | 0-89 | 2100*2100 |

| ALM-ZB8" ; | 203*6000 | 20 | 11 | 10481 | 0-89 | 1800* 1800 |

| AM-ZB9* | 230*6000 | 16 | 11 | 10764 | 0一9 | 1800*1800 |

Litekanyetso tsa Remarka Technical tse kaholimo ke tsa litšupiso tsa hau feela.Lintlha tse felletseng li tlas'a konteraka ea ho qetela.

1) Letlapa le ts'oanang la ho lahla hot-top le sebelisa sejana se kopaneng sa phepelo le kabo ho hokahanya liforomo tse ngata tse chesang, e le hore boemo ba mokelikeli oa tšepe ka har'a hlobo e 'ngoe le e' ngoe sehlopheng sohle sa li-disk tsa ho lahla bo be boemong bo lekanang.Sehlopheng sohle sa li-discs tsa ho lahlela boemong bo tšoanang, mokelikeli oa aluminium o phallang o phalla tlas'a filimi ea aluminium oxide e neng e entsoe pele, e thibelang tšilafalo ea bobeli le ho chesoa ha oxidative ea tšepe.

2) Ka nako e ts'oanang, molemong oa ho sebelisa sefofane se otlolohileng ka botlalo, hlobo e ka etsoa e le hlobo e khuts'oane e hlophisitsoeng hantle ho hlokomela ho lahla ha melamu e mengata.

3) Ka lebaka la palo e kholo ea aluminium e qhibilihisitsoeng le mocheso o fokolang oa mocheso tseleng, mocheso oa ho lahla o ka fokotseha, e le hore tekanyo ea kristale ea subcooling e be khōlō, sekhahla sa nucleation se ikemetseng se phahame, 'me lithollo li hloekisoa.Ntle le litšoaneleho tsa tlhaho tsa hlobo e khuts'oane, aluminium e qhibilihisitsoeng ke Bophahamo bo sebetsang ba kristallise ka har'a hlobo bo bokhuts'oane ho feta bo tloaelehileng ba ho chesa holimo, botebo ba sekoti sa mokelikeli ha bo na botebo, karolo ea karohano ea molamu oa molamu o mosesaane. , lithollo li tšoana haholo, 'me ponahalo e boreleli.

4) Thepa e bokelloa ka kakaretso, ke hore, sethala sa ho lahla le setsi sa dummy se behiloe mme se kopanngoa esale pele, ebe se kenngoa ka chassis ea mochini oa ho lahla le mochini oa ho theola, ebe o sebelisoa hammoho le thapo ya terata kapa hydraulic guide column lift.

2. Melemo ea lihlahisoa

1) Moralo oa trapezoidal o amoheloa bakeng sa phallo ea phallo ea poleiti e kaholimo ea hlobo, e ka fokotsang ts'ebetso ea ho fanyeha aluminium nakong ea ts'ebetso ea ho emisa, ka hona ho eketsa bophelo ba ts'ebeletso ea poleiti ea shunt.

2) Letlapa le ka holimo la lefu le amohela moralo o kopantsoeng oa tube ea tataiso le poleiti ea adapter ho qoba ts'ebetso ea aluminizing le ho taka holim'a molamu oa aluminium, 'me ka nako e ts'oanang, e ka fokotsa litšenyehelo tsa ho roala likarolo.

3) Ho pholile ho potoloha ha metsi ka hare ho amoheloa, phello ea ho boloka mocheso oa poleiti ea diverter le groove e kholo e ntle, ho fetoha ha boemo ba mokelikeli nakong ea ho lahla ho nyenyane, 'me ha ho bonolo ho jara slag le slag.