mokotla oa mofuta oa filthara mokelli oa lerole bakeng sa sebōpi se qhibilihang sa aluminium

Mokelli oa lerōle oa mofuta oa pulse o sebelisetsoa libopi tse qhibilihisang koporo, libopi tsa aluminium tse lahlang, limela tse kopanyang asphalt, mechini e silang, lerōle la ontong le pokello e meng ea lerōle le lits'ebetso tsa desulphurization.

Liindasteri tse sebetsang:Indasteri ea ho lahla aluminium

Sebaka sa Showroom:Ha ho letho

Tlhahlobo ea video e hlahang:E fumaneha

Tlaleho ea Teko ea Mechini:E fumaneha

Warranty ea likarolo tsa mantlha:1 Selemo

Core Components:Enjene, Enjene, mokotla oa sefe

Boemo:E ncha

Boholo bo Nyenyane:0.3 -0.5 μm

Sebaka sa Tšimoloho:Foshan Guangdong, China

Boemo(L*W*H):1830mm X 3910 limilimithara X 6120mm

Boima ba 'mele:8100 lik'hilograma

Tiisetso:1 Selemo

Boholo:tloaelo

Ka mor'a thekisoTšebeletso e Fanoe: Tšehetso ea tekheniki ea video

| Lebitso | Sesefa sa mokotla oa pulse |

| Mofuta | tloaelo |

| Brand | lvyuan |

| Lintho tse bonahalang | Masela a tšepe, a sa lohiloeng, joalo-joalo. |

| Mmala | tloaelo |

| Mosebetsi | Molitu oa sefahla sa tšireletso ea tikoloho |

| Sebopeho | ka tloaelo |

| Tšebeliso | Ho tlosa lerole la workshop |

Lintho tsa 'mele le tsa lik'hemik'hale tsa lerōle la indasteri li fapane,' me tlhaho le tekanyo ea kotsi 'meleng oa motho le tsona li fapane.Sesefa sa mokotla oa pulse se ntlafalitsoeng ke k'hamphani ea rona ho tloha mohopolong oa mantlha oa ho sireletsa polokeho ea basebetsi le tlhahiso e phetseng hantle ke mofuta o sebelisoang haholo Sistimi ea ho tlosa lerōle e netefatsa ho tlosoa ha lerōle ka botlalo, ho hloekisoa hantle, le tlhokomelo e bonolo ntle le ho fetola litšobotsi tsa lerōle. .E 'nile ea sebelisoa likarolong tsohle tsa bophelo' me e loketse metallurgy, mapolanka, thepa ea mohaho, samente, mechine le boenjiniere ba lik'hemik'hale, motlakase, Ho hloekisoa ha lerōle le khase le ho tsosolosoa ha thepa indastering ea leseli.

1. Mokokelli oa lerōle oa pulse o sebelisa theknoloji ea ho hloekisa sefofane sa sefofane sa sub-stop air-stop pulse jet, e hlōlang mefokolo ea batho ba tloaelehileng ba bokellang lerōle le ba bokellang lerōle ka morao.E na le bokhoni bo matla ba ho hloekisa lerōle, bokhoni bo phahameng ba ho bokella lerōle, khatello e tlase ea mosi, le sekhahla sa ho lutla ha moea.Tšebeliso e nyane, e fokolang ea matla, tšebeliso e fokolang ea tšepe, sebaka se fokolang sa fatše, ts'ebetso e tsitsitseng le e tšepahalang, le melemo e metle ea moruo.E loketse ho hloekisoa ha khase e lerōle le ho hlaphoheloa ha thepa ka metallurgy, thepa ea mohaho, samente, mechine, indasteri ea lik'hemik'hale, matla a motlakase le indasteri e khanyang.

2. Pulse off-line lerōle ho hloekisa, katleho ea pokello ea lerōle e phahametse 99.9% kapa ho feta, lerōle ha le na adsorption ea bobeli, 'me mochine oa ho hlatsoa lehlabathe o loketse ho sebetsana le khase e phahameng ea concentration flue.

3. Tlhokomelo le phetoho ea mekotla e ka etsoa ka likamoreng tse arohaneng tlas'a maemo a tloaelehileng a ts'ebetso ea tsamaiso ntle le ho emisa fan ea tsamaiso.Molomo oa mokotla oa filthara o amohela selikalikoe sa katoloso ea elastic, e nang le ts'ebetso e ntle ea ho tiisa ebile e tiile ebile e ka tšeptjoa.Keel ea mokotla oa filthara e nka sebopeho sa polygonal, se fokotsang khohlano lipakeng tsa mokotla le keel, se lelefatsa bophelo ba mokotla, 'me se thusa ho theoloa ha mokotla.

4. Mokhoa o ka holimo oa ho ntša mokotla o amoheloa.Ka mor'a hore skeleton e ntšoe ha ho fetoloa mokotla, mokotla o litšila o kenngoa ka har'a molora karolong e ka tlaase ea lebokose ebe o ntšoa ka mokoting, e leng ho ntlafatsang maemo a ts'ebetso ea ho fetoha ha mokotla.

5. 'Mele oa lebokose o entsoe ka ho tiisa moea, o nang le ts'ebetso e ntle ea ho tiisa.Monyako oa ho hlahloba o sebelisa lisebelisoa tse ntle tsa ho tiisa.Nakong ea ts'ebetso ea tlhahiso, parafine e sebelisoa ho bona ho lutla, 'me sekhahla sa ho lutla ha moea se tlase haholo.

6. Li-ducts tsa moea tse kenang le tse tsoang li hlophisitsoe ka mokhoa o kopanetsoeng 'me ho hanyetsa ha moea ho nyenyane.

7. Taolo ea k'homphieutha e ikemetseng ka ho feletseng, mochine oa ho hlatsoa lehlabathe oa lebili o bonolo ho sebetsa ebile o na le botšepehi bo botle.

8. Tšebeliso ea lisebelisoa tse ncha tsa filimi ea microporous ea FMS le mokhoa o tšepahalang oa ho latela mocheso oa khase ea flue o ka ikamahanya le maemo a fapaneng a khase ea flue.

9. Sebopeho sa lebokose la moea se fokotsa tahlehelo ea ho hanyetsa sebakeng seo 'me se qoba ho kenngoa ho sa thabiseng ha mokotla oa filthara.

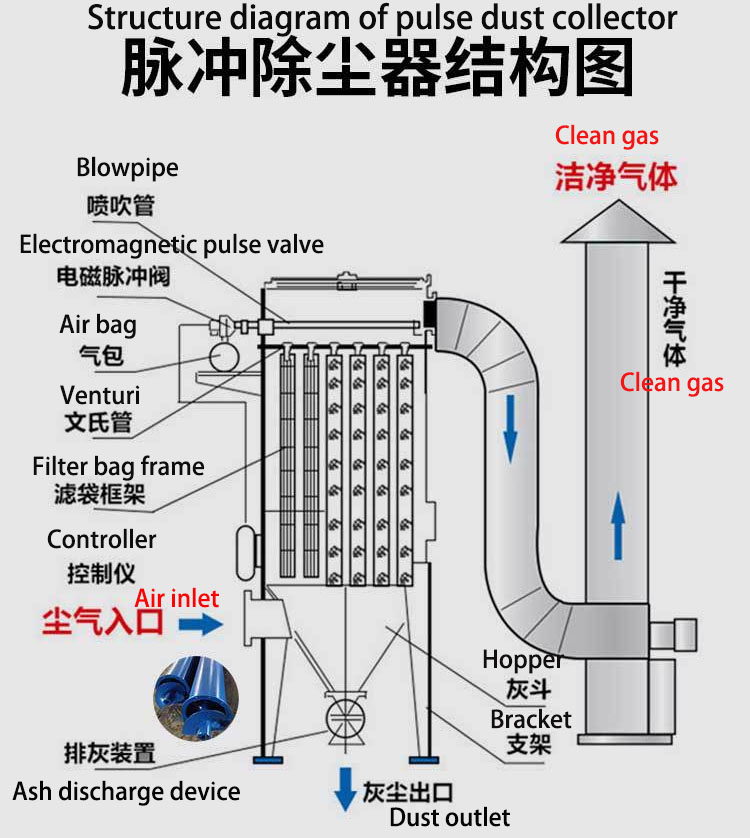

1.Pipe e butsoang e na le boikarabelo ba ho foka le ho khelosa.

2. The electromagnetic pulse valve ke boikarabelo ba ho bula le ho koala moea o hatelitsoeng.

3. Mokotla oa moea, boloka moea o hatelitsoeng.

4. Mokotla oa lesela oa ho tlosa lerōle, karolo ea mantlha ea ho sefa lerōle.

5. Ho tlosa lerōle letlooa lesaka, tšehetsa lerōle ho tloswa lesela mokotla.

6. Molaoli o na le boikarabelo ba ho laola ho bula le ho koala moea o hatelitsoeng le mosebetsi oa tsamaiso ea molora.

7. Lebanta la conveyor air shutter (motlakase moea shutter) tsoela pele ho ntša thepa ka mokelli lerōle ka nako.

8. Moferefere o fokotsa ho ntša lerata la enjene.

9. Laola lebokose la motlakase, taolo le lisebelisoa tsa ho qala.10. Fane e eketsa khatello ea khase ho ntša khase.